Products

Perfect Performance, Vision Alignment Rework Station.

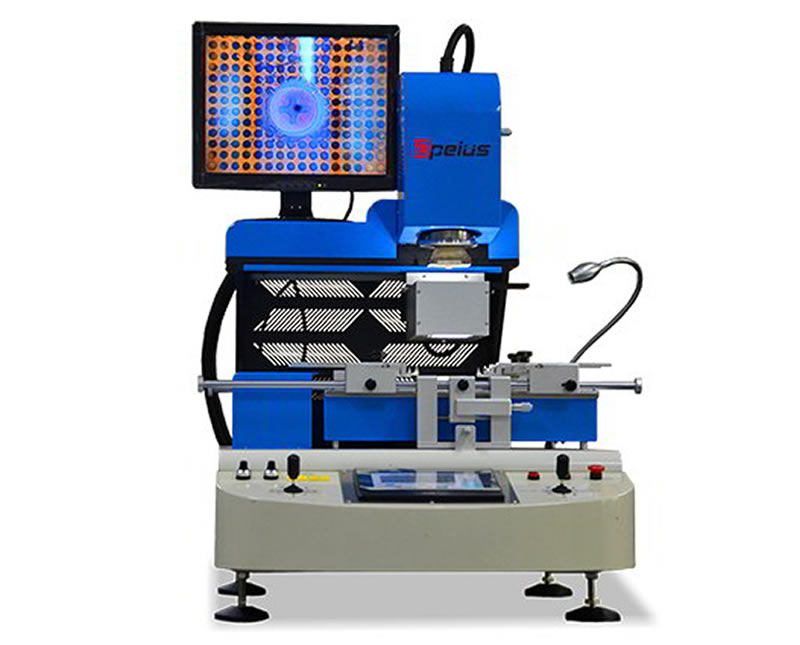

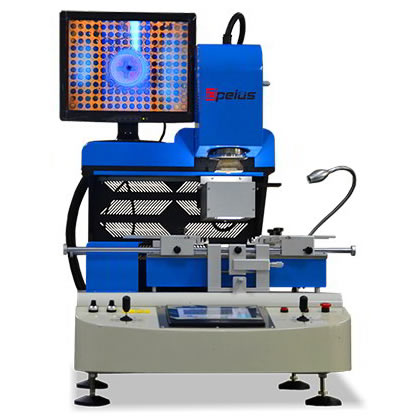

Master-1000 BGA Rework Station

Master-1000 loaded with features that make it the industry’s most reliable and affordable solution for the widest range of SMT repairs. Safe Removal, High-Precision Placement, and Perfect Soldering for Any SMD Repair Applications.

- High-definition optical alignment system(1080p).

- Automatic / Joystick control X- and Y-axis optics positioning.

- Automatic / Joystick control Z-axis for removal, placement, soldering.

- Micrometer-adjust X-, Y-, and Ø-axis lead-to-pad alignment.

- Four thermocouple inputs.

- 415*360mm IR Bottom heater.

Features

● Touch screen with human interface,heating time, heating temperature, reflow temperature rate, advanced alarming, vacuum time all can set inside the touch screen, simple operation, easy learn.

● PLC import from Japan, temperature control module use China famous brand, display three temperature curves, 4pcs independent temperature sensor, which can measure the different place temperature of the chips, make sure the rework rate.

● Three independent heating temperature zone, each heating temperature zone can independently set the heating temperature, heating time, rate; six heating temperature sections, Simulate the reflow oven heating mode [preheating, constant, warming, soldering, reflow soldering, cooling].

● Auto feed chips, pick up chips, blowing chips; auto recognition chips place during alignment Multifunction mode [weld, remove, mount, manual], realize semi auto and auto function, meet customer’s requirement.

● High precision K-type Closed Loop import from USA together with our company special heating way, the soldering rang of temperature within±1°C.

● Imported optical alignment system with 15’ high definition monitor; high precision micrometer adjust X/Y/R axis; make sure the alignment precision within 0.01-0.02mm.

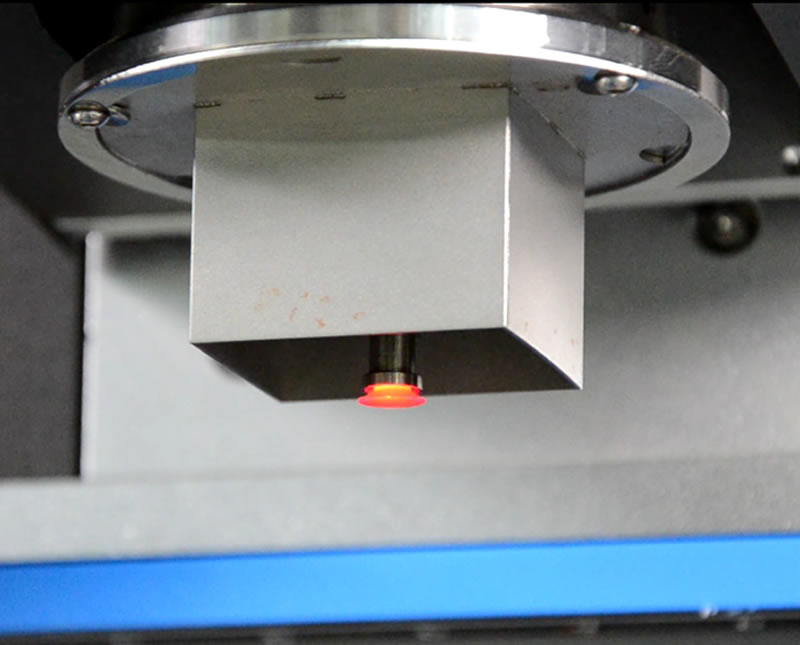

● Top heater and mounting heater design2 in 1 which can make the mounting more precision; there are many sizes of BGA nozzles which can meet different chips sizes, BGA nozzles can easy change, we accept customize.

● High automatic and precision, Completely avoid human operation error; it is good for reworking lead free craft and double BGA, QFN, QFP, capacitance-type resistor components which can achieve good result.

● Additional monitoring camera which can observe the solder ball melting and easy to check the temperature curve and the soldering result(optional function).

Specifications

| Model | Master-1000 |

| Power | 6800W |

| Up heater power | 1200W |

| Down heater power | 1200W |

| IR heater power | 4200W (2400W area is independently control) |

| Power supply | (Single Phase) AC 230V 50/60Hz |

| Optics | HD Split-vision system |

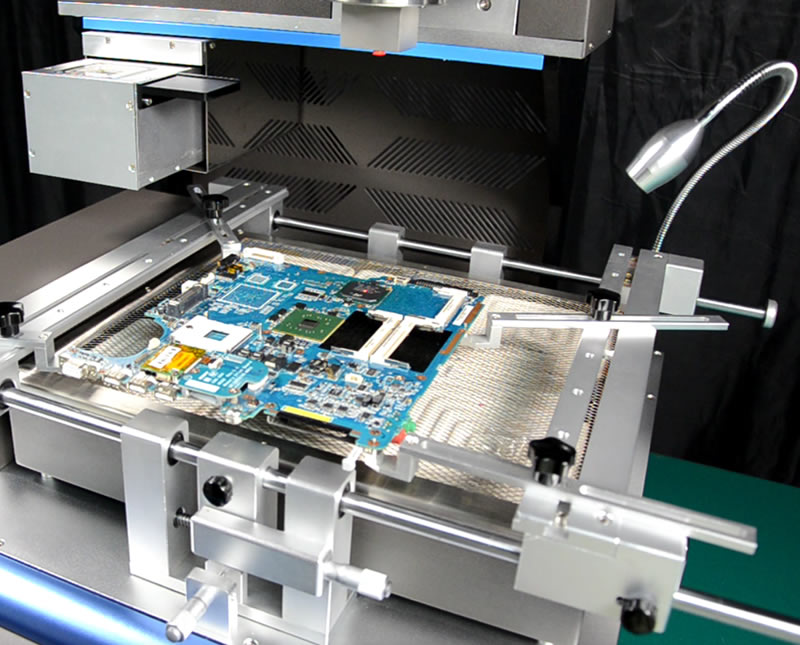

| PCB Size | Min: 50×50mm Max: 500×450mm |

| Component size | 0.6mm-80mm (Optional Special designed picking nozzle for small chips) |

| Thermo-couple Ports | 4pcs |

| PCB thickness | 1.0-5mm |

| Mounting precision | ±0.01mm |

| Size | L670×W780×H850mm |

| Weight | About 90kg |